“If you want to measure your own interests, put your own interests behind, and at the expense of this, measure the interests of the other party first. Make up for your own sacrifice provided to the other party with your own efforts and ingenuity. Prosperity, and by extension, the ultimate will always bring about results that are in your own interest. Based on the founding spirit of altruism, customer satisfaction is always pursued, and a safe and secure society is created through further evolution of disaster prevention and mitigation technologies. With the contributor “New Business Contractor”, Tobishima Construction Co., Ltd., from August 29 to 30, 2020, non-GNSS that does not receive radio waves such as GPS * Ortho image and 3D by automatic flight in a tunnel under the environment I worked on creating a point group. (* Global Navigation Satellite System / Global Positioning Satellite System, a general term for satellite positioning systems such as GPS)

Since large heavy machinery is used in tunnel construction, it is a dangerous site that can cause a serious accident when it comes into contact with people. It is not easy to check the excavation status at such a site. Normally, flying a drone at an indoor site where self-position estimation by GNSS radio waves is not possible requires advanced technology by the operator. Aerobo Inspection, a new inspection drone developed by Aerosense Co., Ltd., automatically flies even in a non-GNSS environment, flies within a specified range without the skill of the operator, and takes pictures. I was able to come. In the future, we will contribute to people’s safe society at various sites such as near buildings where GNSS radio waves are difficult to enter, as well as flying in tunnels.

STATE AT THE TIME OF AERIAL PHOTOGRAPHY:

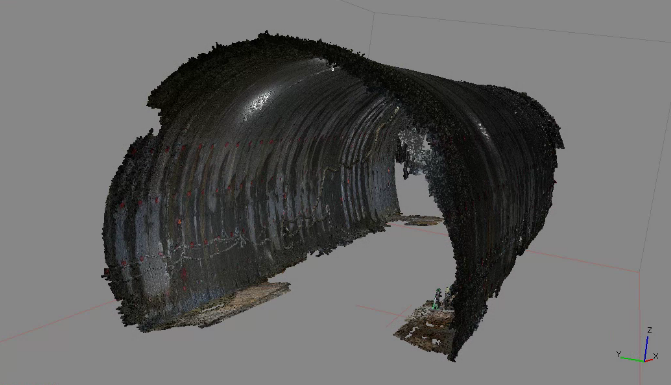

On the day of the flight, I took an aerial photograph of the wall surface near the face by autonomous flight. Not only the lighting inside the tunnel, but also the aircraft was illuminated for stable flight, and orthophotos and 3D point clouds that can be effectively used for tunnel inspection were created. When we measured the distance between the lock bolts in the tunnel, the error between the distances measured in the 3D point cloud was small, and we were able to collect the data in a form close to the actual size. In addition, we mounted the camera on the top of the drone body and shot a video toward the face, confirming that both automatic flight and manual flight are possible.

3D point cloud created in our cloud

EVALUATION AFTER USE MR. KATSUBE, R & D GROUP NO. 1 LABORATORY, TECHNICAL RESEARCH INSTITUTE:

While proceeding with various developments with a view to actively utilizing 3D point clouds, Aerosense was asked to carry out aerobo surveying in the earthquake disaster reconstruction project in Minamisanriku Town, so in the tunnel We spoke for joint verification of 3D surveying in the tunnel, which leads to automatic navigation and finished surveying. The inside of the tunnel is not only a non-GNSS environment, but also a harsh space for drones due to the narrowness due to the placement of various heavy machinery and the local wind caused by the air duct. Even under these conditions, I was surprised that the flight was stable. I hope to continue the cooperative relationship in the future. I look forward to working with you.

FROM AEROSENSE TO TOBISHIMA CORPORATION:

This time, we jointly verified the use of drones in the tunnel. It was my first experience to fly in a tunnel during excavation, so I was nervous, but the people at the site warmly welcomed me and I was able to succeed in the experiment. Thank you from the bottom of my heart. The inside of the tunnel was much brighter than I had imagined, the equipment was tidy, and it was a series of surprises, but I took into account the issues that I could confirm at this site and the needs of the site from Mr. Katsube of Tobishima Corporation. We will continue to improve non-GNSS environmentally friendly inspection drones and aerobo inspection. We look forward to working with you in the future.